production

EXTRUSION - ANODISING - THERMAL COATING

THERMAL BREAK

FINISHING - LABELS

Extrusion consists of forcing a billet of aluminum, heated to about 500 °C, to flow through a metal die, the latter having the shape of the desired profile.

- 3 extrusion presses

- Between 1,700 and 2,800 tons of pressure

- 27,000 tons of annual production capacity

Extrusion

Extrusion consists of forcing a billet of aluminum, heated to about 500 °C, to flow through a metal die, the latter having the shape of the desired profile.

- 3 extrusion presses

- Between 1,700 and 2,800 tons of pressure

- 27,000 tons of annual production capacity

Anodizing is a surface treatment that industrially reproduces the natural phenomenon of oxidation by forming a protective oxide layer, which enhances the strength and protection of the metal against corrosion. Anodized profiles can be supplied with a satin or glossy finish, in a wide range of shades: clear, grey, silver, bronze, black, gold, etc. All are in compliance with Qualanod specifications. The thickness of the anodic oxide coating, depending on requirements, complies with classes 5, 10, 15, or 20 microns.

- 1 anodizing line of 30,000 AMPS

- 3,000 tons of annual capacity

Anodizing is a surface treatment that industrially reproduces the natural phenomenon of oxidation by forming a protective oxide layer, which enhances the strength and protection of the metal against corrosion. Anodized profiles can be supplied with a satin or glossy finish, in a wide range of shades: clear, grey, silver, bronze, black, gold, etc. All are in compliance with Qualanod specifications. The thickness of the anodic oxide coating, depending on requirements, complies with classes 5, 10, 15, or 20 microns.

- 1 anodizing line of 30,000 AMPS

- 3,000 tons of annual capacity

Powder coating consists of applying a colored polyester powder, in compliance with Qualicoat recommendations, which after baking transforms into a hard and resistant film. It offers a wide range of aesthetic options with an extensive palette of colors and specific textures that can be applied to all systems.

Our workshop also includes a sublimation service (film on powder), allowing the reproduction of specific decorative effects such as wood, marble, or other customized patterns, for an even more refined and tailor-made finish.

- 3 powder coating lines: horizontal and vertical

- 21,000 tons of annual capacity

THERMOLAQUAGE

Powder coating consists of applying a colored polyester powder, in compliance with Qualicoat recommendations, which after baking transforms into a hard and resistant film. It offers a wide range of aesthetic options with an extensive palette of colors and specific textures that can be applied to all systems.

Our workshop also includes a sublimation service (film on powder), allowing the reproduction of specific decorative effects such as wood, marble, or other customized patterns, for an even more refined and tailor-made finish.

- 3 powder coating lines: horizontal and vertical

- 21,000 tons of annual capacity

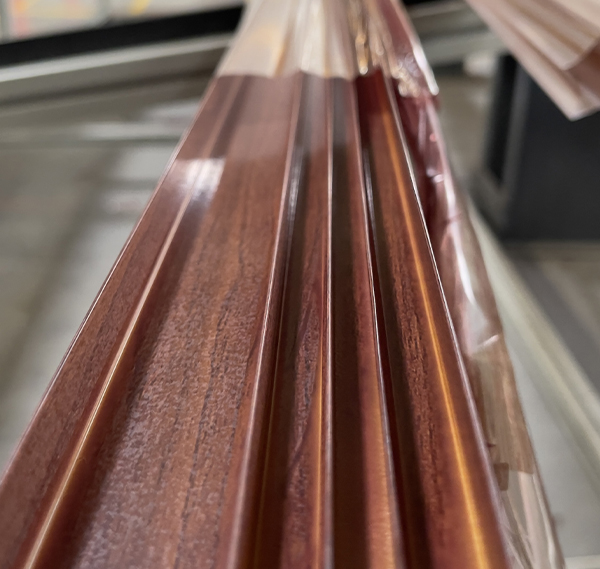

Sublimation:

The profile is pre-painted with powder coating, creating a protective and decorative layer. In the second phase, the profile is covered by a thermal sublimation transfer, previously printed with the wood effect chosen by the client.

- 400 tons of annual capacity

Powder on powder:

Application of two consecutive layers of polyester powder, providing the ideal tone to imitate the desired type of wood. This finish combines the aesthetic appearance of wood with anti-corrosion quality, without requiring the costly maintenance of real wood.

- 1,000 tons of annual capacity

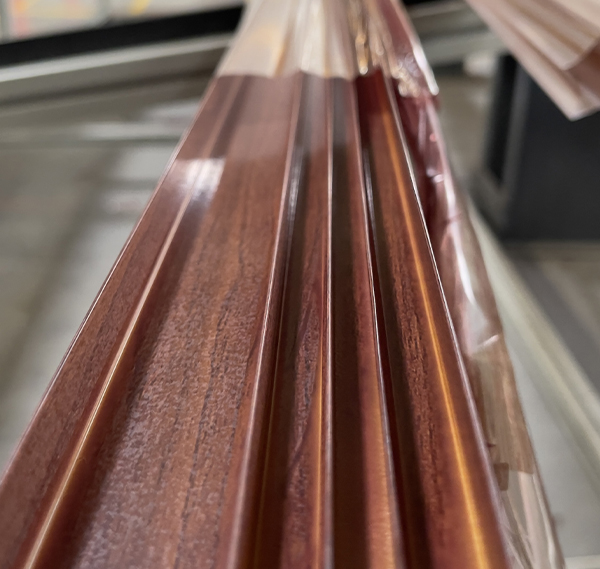

Sublimation:

The profile is pre-painted with powder coating, creating a protective and decorative layer. In the second phase, the profile is covered by a thermal sublimation transfer, previously printed with the wood effect chosen by the client.

- 400 tons of annual capacity

Powder on powder:

Application of two consecutive layers of polyester powder, providing the ideal tone to imitate the desired type of wood. This finish combines the aesthetic appearance of wood with anti-corrosion quality, without requiring the costly maintenance of real wood.

- 1,000 tons of annual capacity

Assembly of thermal break profile lines using polyamide strips, certified by the Scientific and Technical Center for Building (CSTB). This technique ensures perfect thermal and acoustic insulation.

- 3 assembly lines

- 1,500 tons of annual capacity

- 3 assembly lines

- 1,500 tons of annual capacity

Our finishing workshop is equipped with a 3-axis automatic CNC machine that performs various machining operations on demand, producing up to 600 pieces per day, with an annual production capacity of 500 tons:

- Cutting to length

- Milling

- Drilling

- Stamping

- Assembly of accessories and gaskets

Our finishing workshop is equipped with a 3-axis automatic CNC machine that carries out various machining operations on demand, producing up to 600 pieces per day, with an annual production capacity of 500 tons:

- Cutting to length

- Milling

- Drilling

- Stamping

- Assembly of accessories and seals

Labels de qualité

LABEL QUALANOD

Certificat n°1900

Délivré le 02/05/1995 par ADAL

Concerne les produits en aluminium anodisés par anodisation sulfurique.

Ce label est délivré et régulièrement contrôlé par l’ADAL

Association pour le développement de l’Aluminium Anodisé ou Laquéic or web designs.

LABEL QUALICOAT QUALIDECO

Certificat n°MA-0001

Délivré le 30/11/2006 par QUALICOAT

Concerne la décoration effet bois

poudre sur poudre.

Ce label est délivré par L’Association Internationale QUALICOAT

Label international de traitement de surface en aluminium

LABEL QUALICOAT SEASIDE

Certificat n°1100

Délivré le 11/11/1994 par QUALICOAT

Concerne les produits en aluminium thermolaqués, prévus notamment pour une utilisation en bord de mer.

Ce label est délivré par L’Association Internationale QUALICOAT

Label international de traitement de surface en aluminium

LABEL QUALIMARINE

Certificat n°QM-021

Délivré le 03/10/2000 par ADAL

Concerne la préparation de la surface pour les installations prévues en bord de mer.

Ce label est délivré et régulièrement contrôlé par l’ADAL

Association pour le développement de l’Aluminium Anodisé ou Laqué

LABEL QUALILAQUAGE

Certificat n° QL-022

Délivré le 31/07/2019 par ADAL

Concerne les produits en aluminium

thermolaqués.

Ce label est délivré et régulièrement contrôlé par l’ADAL

Association pour le développement de l’Aluminium Anodisé ou Laqué